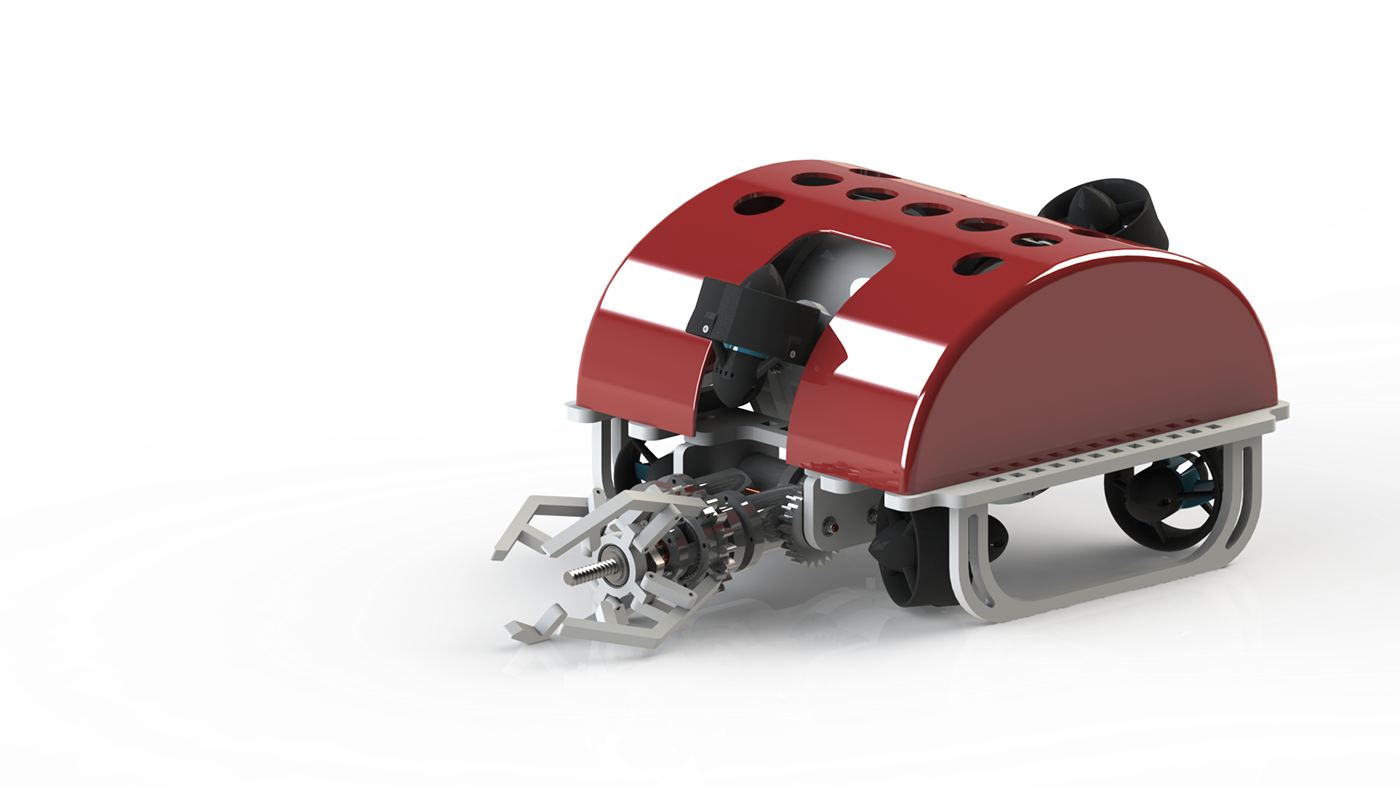

This prototype was built to compete in the Marine Advanced Technology Education (MATE) Center's ROV competition.The main objective of the competition is to build an underwater robot capable of reaching vast depths and dangerous situations that are difficult for human divers to reach. It mimics real-life large-scale underwater missions such as maintaining underwater structures and containing underwater disasters. It is one of a series of designs proposed to Integrate Raptor Team, Alexandria, Egypt.

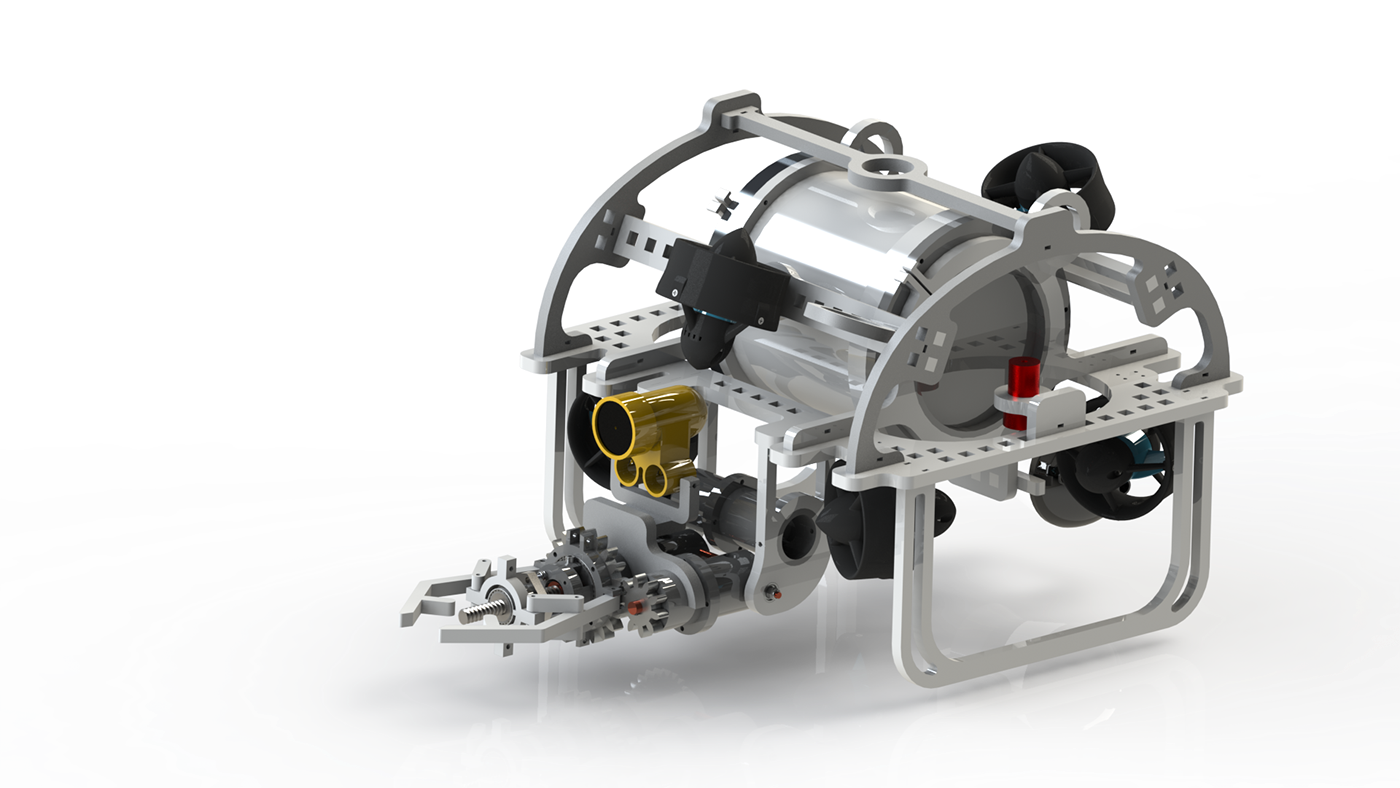

Isolation Being the most important safety precaution, and one of the main aspects of the ROV, we paid special attention in constructing our isolation tube. Featuring three stage O-ring isolation on the right side and one stage with threads on the left side, and two stage chemical isolation on each side. Raptors excelled in producing an isolation tube capable of withstanding decent depths, which enables The Interceptor to dive comfortably in the required tasks. Our isolation tube consists of three components, fitting together as shown in the figure, and secured with bolts and locking nuts.In addition, we made the right side of the isolation tube from metal to cool down the heat generated from the DC converter to keep electric components working efficiently. We chose the metal to be Aluminum because of its good thermal conductivity and suitable density.

ManipulatorAccording to the ROV’s purpose, it is supposed to do many types of missions underwater. So, it will need a multitasking manipulator. And that's what we worked on. We designed a three degree of freedom manipulator, facing a lot of difficulties until we got our last edition.First, we designed the lifting motor in horizontal position, fixed to the ROV chassis by two couplings in line with the motor. The principle of lifting depends on the reaction on the motor. While the motor is fixed in a case, the couplings are concentric to the sides of the case by bearings and fixed to the chassis. So, when the motor run, the shaft will not rotate, but the motor will rotate itself.Next, a gripper motor concentric with a cylinder is fixed to the case of the lifting motor, this motor is to open and close the end-effector using a ball screw. We chose the ball screw for its useful functions, such as its low friction and zero backlash. In addition, it transfers the rotational motion to linear smoothly, which is perfect for a reliable operation.

** All designs and illustrations are made using SolidWorks 2016 **

设计师还没有其他作品哦

确认要删除该条评论吗?

小小心意,大大鼓励

最高赞赏200元

使用支付宝扫描二维码完成支付

使用微信扫描二维码完成支付

当前余额:¥0.00

支付操作会向你普象账户的注册手机号发送验证码

请注意查收

扫一扫添加

普象商务

扫一扫添加

客服微信

扫一扫下载

手机APP

留言板(0)